CHANCE® Helical Piles – The World’s Anchoring & Foundation System

CHANCE® Helical Piles – The World’s Anchoring & Foundation System

Mason Grady Foundations is proud to be partnered with CHANCE, the world’s leading helical foundation and anchoring manufacturer. The CHANCE® Helical Pile system offers a technically advanced, cost effective alternative to other pile systems and is backed by over 100 years of engineering experience.

CHANCE’s product line allows us to use helical foundations in a wide range of applications—including applications where other manufacturers’ systems are inadequate. All of our products are installed by CHANCE Certified Installers.

- Tested for Quality- ICC-ES Accredited Test Lab

- Building Code Approved

- ISO 9001 Certified

- Product Traceability

- Ability to custom design

- High Capacity Products

- Hot-Dipped Galvanized

- Made in the USA

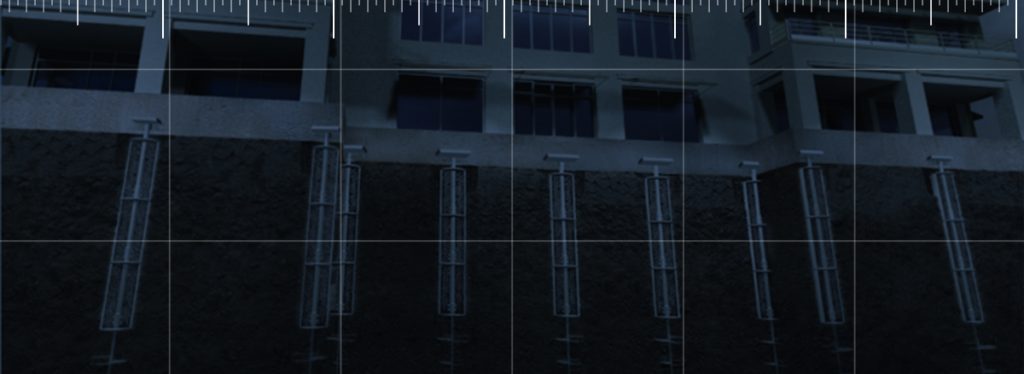

Helical piles are an end-bearing deep foundation system that has applications in both compression and tension. By applying torque to the shaft this action installs the helical pile with minimal displacement or disturbance. No vibrations or spoils are created during installation. Loads are transferred down the shaft onto the helical plates and into the minimally disturbed load bearing soil beneath or above each helical plate. The resistance required to torque the helical pile into the soil directly correlates to its capacity – the greater the resistance (torque) the denser the soil and the higher the load carrying capabilities. It is a fast and lightweight method that is approved by national building code agencies, and is the deep foundation system of choice for architects, builders, and engineers alike.

Helical piles are an end-bearing deep foundation system that has applications in both compression and tension. By applying torque to the shaft this action installs the helical pile with minimal displacement or disturbance. No vibrations or spoils are created during installation. Loads are transferred down the shaft onto the helical plates and into the minimally disturbed load bearing soil beneath or above each helical plate. The resistance required to torque the helical pile into the soil directly correlates to its capacity – the greater the resistance (torque) the denser the soil and the higher the load carrying capabilities. It is a fast and lightweight method that is approved by national building code agencies, and is the deep foundation system of choice for architects, builders, and engineers alike.

Advantages of Helical Piles

- Eliminates high-mobilization costs that are associated with driven piles, drilled shafts or auger-cast piles

- Immediate torque-to-capacity feedback for production control

- Minimizes soil disturbance during installation

- Uses common construction equipment easily fitted with hydraulically-driven torque motors

- No excavation, vibrations or spoils

- Quick installation when compared to traditional deep foundation solutions

- Can be loaded immediately upon completion

- Approved for use by building code agencies

- Easy to use in limited access areas, areas with high water tables, and weak surface soils

- Can be modified in the field

- Capacities up to 210 kips ULT

- Predictable load capacities

- Installation in environmentally sensitive areas

Case Studies:

- Industrial New Construction Project – Flagler County Aircraft Hangar

- Industrial New Construction Project – Bay Line Railroad

- Commercial New Construction Project – BJ’s Restaurant and Brewhouse

- Residential New Construction Project

Brochures: